.jpg)

This National T-Level week, we are celebrating the fantastic work produced by our students who are part of the two T-Level courses we offer - Design and Development for Engineering and Manufacturing and Digital Software Development.

These are two fields that are driving innovation and digital transformation. It is inspiring to see how their skills and projects are complementing each other, with Digital students creating applications to help Engineering students learn and hone their craft.

Hands-On Skills in Our Engineering Workshop

Our Engineering and Manufacturing students are trained in both traditional and cutting-edge production methods, preparing them for the modern factory floor. Students are spending crucial time in the engineering facilities, mastering industry-standard hand modelling and fitting techniques that form the foundation of practical engineering. These essential skills are what they carry forward into their industry placements.

Students tackle projects with precision and care, developing skills including:

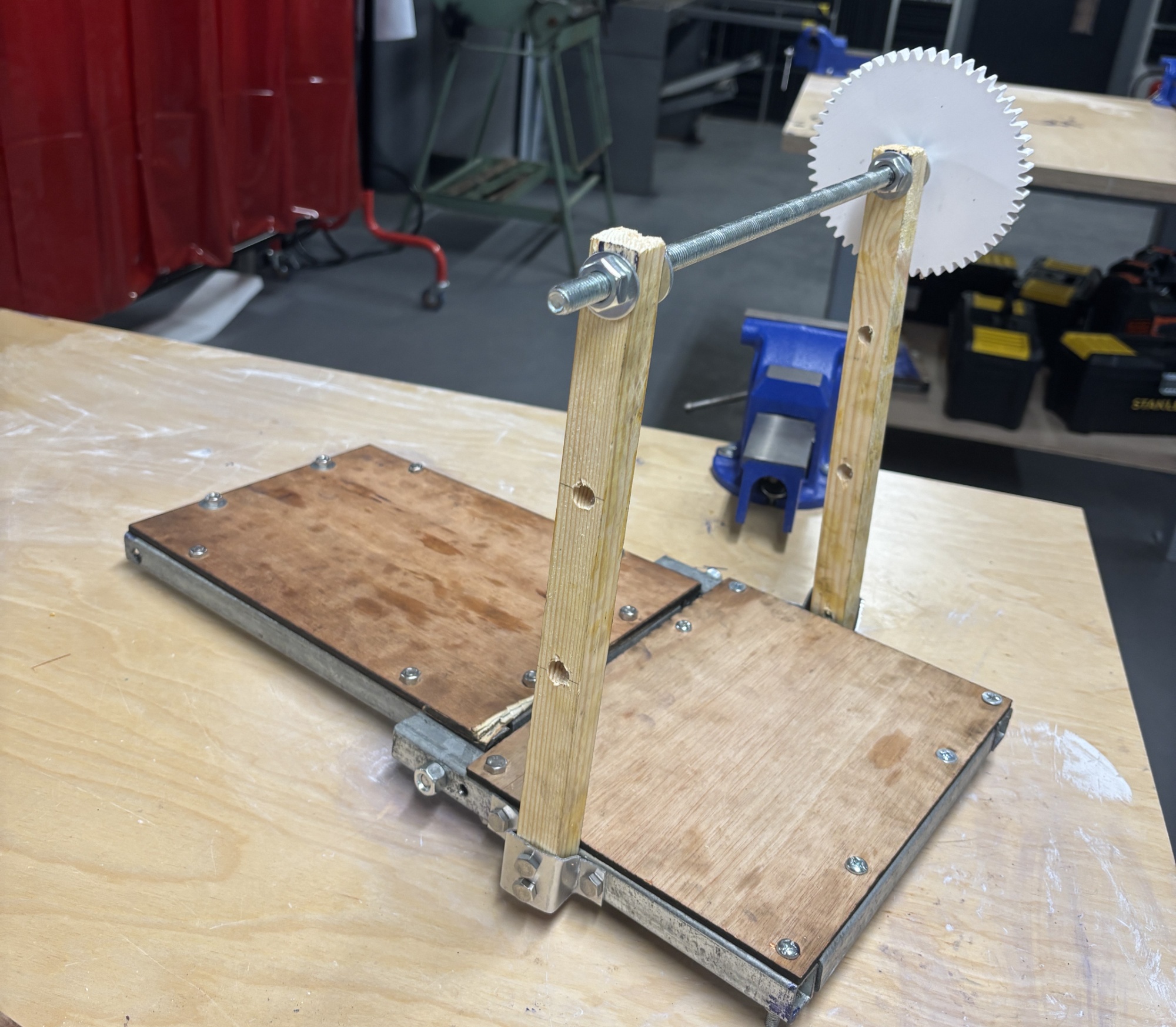

Hand Fitting Techniques: Students are using a variety of tools for manufacturing and assembly work, such as the construction of the model drawbridge. This involves precision skills like screwing and hand threading.

CNC Machining: Students utilise Computer Numerical Control (CNC) machines in the workshop, learning to programme and operate automated tools that deliver high-precision, repeatable results for complex components.

Cam System Model: Students are also developing their understanding of mechanical principles by building Cam system models, which illustrate how to transfer rotational motion into linear motion.

Additive Manufacturing: Students create three-dimensional objects by building them up layer by layer from a digital model (like a CAD file). This method uses materials such as plastics, metals, and ceramics and is vital for rapid prototyping, creating specialised tools, and even mass production in modern industry.

Mastering Modern Manufacturing

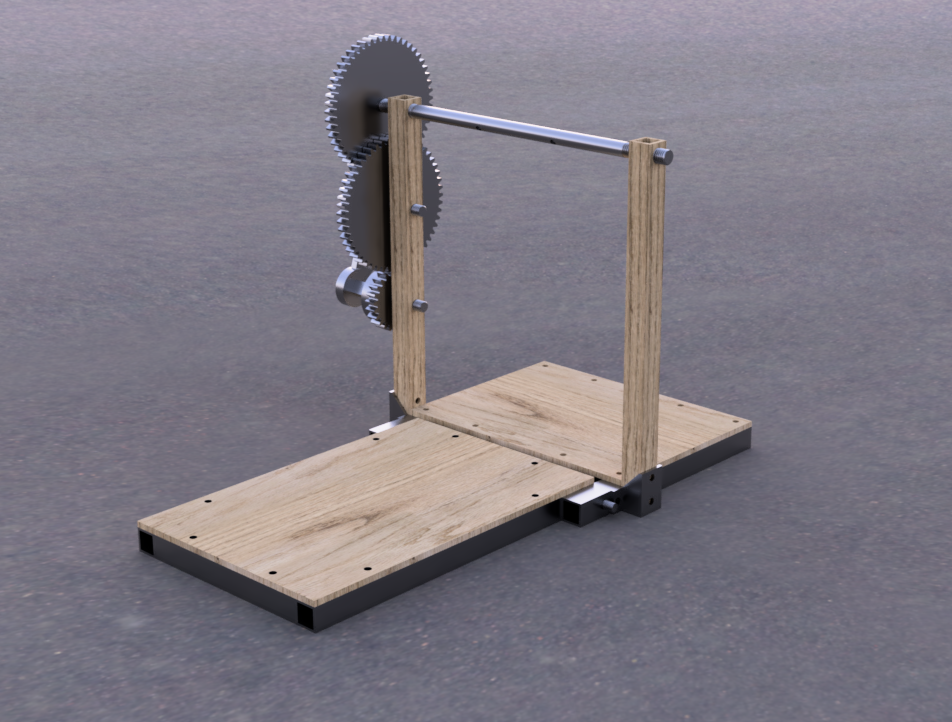

Here are the latest T-Level students' manufacturing and assembly work on a model drawbridge giving them different hand fitting techniques such as screwing, hand threading... lots of techniques used in industry.

Students modelled them first in Autodesk Fusion 360 Software with the working handle and gears.

Digital Software Development Augmented Reality Project

The connection between physical engineering and digital innovation is clear, with our students creating projects that are both grounded in practical skills and elevated by cutting-edge technology.

One of our talented Digital T-Level students, Daisy, created an incredible AR tour of our workshop facilities. This powerful AR experience was built using Godot Engine and Claude AI for code generation. The final design was then built into Meta, demonstrating proficiency with modern digital platforms and AI-assisted development.

This project seamlessly integrates with the Engineering department by providing instructional videos and texts on machine usage as well as essential health and safety information for machinery.

Want to learn more about how this practical training translates into professional success?

See how one of our T-level students got on during his placement at Beverston Engineering.